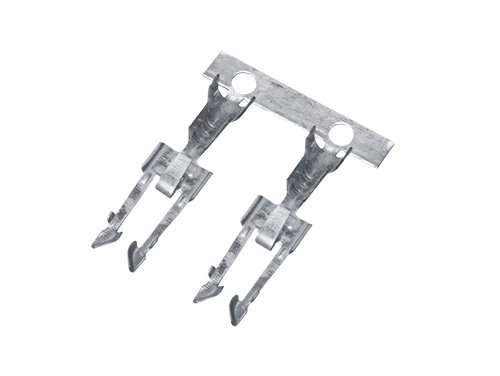

Terminals

We provide the full range of automotive wire harness terminals including Plug Terminals, Socket Terminals, Shur Plug terminals, Splice Terminals, Battery Terminals and Fuse box terminals.

All our Automotive connector terminals come from OEM suppliers, and they can replace the high-priced automotive connector terminals from Japan, Europe and the United States. Our products have been widely used in automotive wiring harness factories, directly supporting well-known automobile brands, so the product quality has been verified by the market.

-

Connector Blade Terminals

We offer both sealed waterproofed terminals and non-sealed terminals with Mating Tab widths: 0.64mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm, 1.8mm, 2.2mm, 2.8mm, 3.00mm, 4.7mm, 5.00mm, 6.00mm, 7.8mm, 9.5mm. They have good versatility, excellent electrical conductivity and plug-in force performance. -

Shur Plug Terminals

Shur-Plug terminal is also called Bullet terminal. We sell them at cheap prices and with small MOQ requirements. -

Splice Terminals

Splice Terminals include R Terminals (also called Ring Tongue terminals), Y terminals (also called Spade Tongue Terminals) and U terminals. -

Battery Terminals

Our Battery Terminals are widely used in different types of automotive, such as Cars, Pickups, Light trucks, Heavy trucks, buses and so on. High quality and good prices. -

Fuse Box Terminals

You can find the terminals special used in Fuse Box. If you also want to buy Fuse Boxes, you can go to our Fuse Box series. -

Other Terminals

Our portfolio of other terminals includes several special shape or purpose terminals used in the automotive industry.