RSGG-T Environment Friendly thick Glue Dual Wall Heat Shrink tubing

Brand: Woer

Type: SBRS - (3X)G

Material: ⑴ EVA ; ⑵ Hot-melt adhesive/thick Glue

State: Soft pipe

Shape: Pipe

Color: Black (Other color available upon request)

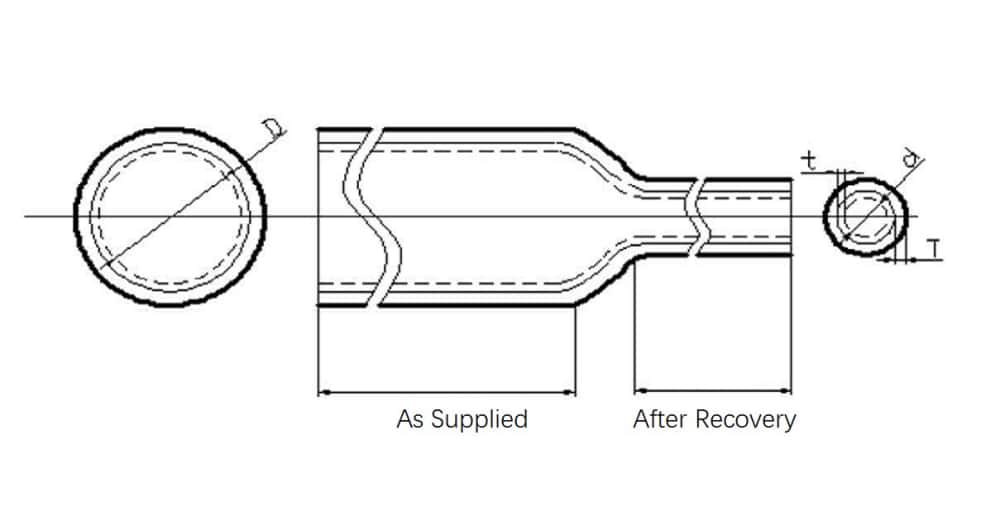

Shrink Ratio: 3:1

Longitudinal Shrink Ratio: ≤±8%

Smell: No

Operation temperature: -45℃~25℃

Rated Voltage: 600V

Shrink temperature: 125℃~200℃

Decompose temperature: 125℃ shrink, but don’t decompose

Flash point: Fire-resistant

Natural temperature: Normal temperature

Explode rate: No

Environment: RoHS Compliant

We also supply this series thick Glue convoluted tubing with different specifications:

|

Parts No. |

Reference No. |

As Supplied Min I D Ø (mm) |

After Recovery Max I.d Ø (mm) |

|

RSGG-T-3.2mm |

RSGG-T-3.2mm |

≥3.2 |

≤1.00 |

|

RSGG-T-4.8mm |

RSGG-T-4.8mm |

≥4.8 |

≤1.60 |

|

RSGG-T-6.4mm |

RSGG-T-6.4mm |

≥6.4 |

≤2.20 |

|

RSGG-T-7.9mm |

RSGG-T-7.9mm |

≥7.9 |

≤2.70 |

|

RSGG-T-9.5mm |

RSGG-T-9.5mm |

≥9.5 |

≤3.20 |

Advantages of heat shrinkable tubing with hot-melt adhesive

1. The shrinkage ratio of hot-melt adhesive tubing is 3:1 or 4:1, the ordinary is 2:1;

2. Wall thickness: the wall thickness of heat shrinkable pipe with glue is about 0.4-0.8, and that of ordinary heat shrinkable pipe is about 0.2-0.5;

3. The heat shrinkable pipe with glue is sealed and waterproof. It is mainly used in shipbuilding, automobile, water pump, submersible pump, outdoor lighting and other fields requiring waterproof. The ordinary heat shrinkable pipe is mainly used for insulation at the connection of wires.

Main components and Raw material

The ordinary heat shrinkable pipe is also called single wall tubing, and the heat shrinkable tubing with hot-melt adhesive is called double wall tubing.

The main component of double wall tubing is Ethylene-vin ylacetate copolymer (EVA), mixed with an appropriate amount of flame retardant, additives and hot-melt adhesive.

The contents of lead (PB), cadmium (CD), mercury (Hg), hexavalent chromium (Cr6+), polybrominated biphenyls (PBBs), polybrominated diphenyl ethers (PBDEs) and other environmental substances in the products comply with SONY-SS-00259 and RoHS2.0(2011/65/EU) directive environmental requirements.

Its main components are as follows

|

Raw material |

Molecular formula |

Application |

Content |

|

Ethylene-vinylacetate copolymer |

(CH2CH2) m-(CH2-CH-COOCH3)n |

Main components |

50% |

|

Magnesium Hydroxide |

Mg(OH)2 |

Flame retardant |

30% |

|

Phosphorus |

P |

Flame retardant |

10% |

|

Anti-oxide |

C35H62O3 |

Antioxidant |

1% |

|

pigment |

----- |

Colorant |

4% |

|

Hot melt adhesive |

----- |

Sealing material |

5% |

|

INK |

----- |

Printing material |

----- |

Product Performance Test

|

PROPERTY |

TEST METHOD |

STANTARD |

|

Tensile Strength(MPa) |

ASTM D2671 |

≥10.4 |

|

Elongation(%) |

ASTM D2671 |

≥200 |

|

Tensile Strength after aging(MPa) |

UL224 158℃×168h |

≥7.3 |

|

Elongation at Break after aging(%) |

UL224 158℃×168h |

≥100 |

|

Dielectric strength(kv/mm) |

IEC 60243 |

≥15 |

|

Volume resistance(Ω.cm) |

IEC 60093 |

≥1×1014 |

Adhesive Property

|

Hot Melting Adhesive Property |

||

|

PROPERTY |

TEST METHOD |

Standard |

|

Water Absorption |

ASTM-D570 |

<0.2% |

|

Vicat Softening Point |

ASTM-E28 |

95℃ |

|

Peel Strength(PE) |

ASTM-D1000 |

120N/25mm |

|

Peel Strength(AL) |

ASTM-D1000 |

80N/25mm |