Polyester fleece Tape meet standard of PSA, Ford and Volkswagen

Basic Information

Name: PET Fleece Tape / Polyester Non-woven Tape

Material: Polyester Non-woven Cloth

Color: Black

Width: 9mm / 19mm / 25mm / 38mm

Length: 11.5m / 15m / 18m / 25m

Core: 38mm

Temperature resistance: -40-+125℃

It is composed of high-quality polyester non-woven, non-rotting polyester and aging stable synthetic rubber-based adhesive. According to the different thickness and temperature resistance, Typhoenix offers different types of fleece tape for your choice as below:

| Product Name | Product Construction | Performance Characteristics | Application Recommendation | ||||||||||

| Total Thickness (μm) |

Carrier | Adhesive | Carrier Thickness (μm) |

Tensile Strength (N/cm) |

Elonga-tion (%) |

Adhesive Strength To Steel (N/cm) |

Adhesive Strength To Backing (N/cm) |

Abrasion Class | Flame Class | Comply with RoHS & REACH |

Maximum Continuous Operating Temperature (℃) |

||

| EF9531 | 280 | PET Non-woven Cloth | Synthetic Rubber | 265 | 40 | 16 | 3 | 4 | B | B | Y | 105 | Wire Harness Wrapping |

| EF9531C | 280 | PET Non-woven Cloth | Synthetic Rubber | 265 | 41 | 18 | 3 | 4 | B | B | Y | 105 | |

| EF9531D | 280 | PET Non-woven Cloth | Natural Rubber | 265 | 40 | 18 | 2.5 | 3 | B | B | Y | 105 | |

| EF9532 | 1000 | PET Non-woven Cloth | Synthetic Rubber | 700 | 35 | 30 | 4 | 3 | D | B | Y | 105 | |

| EF9532E | 750 | PET Non-woven Cloth | Synthetic Rubber | 600 | 33 | 25 | 4 | 3 | D | B | Y | 105 | |

| EF9525 | 1200 | Multi-laminated PET Non-woven Cloth | Acrylic | 950 | 260 | 25 | 3 | 3 | E | B | Y | 125 | |

The model of EF9531 can meet the standard requirement of PSA (9645871099C), Ford (ES-KU5T-1A303-AA) and Volkswagen (VW60360), it can replace TESA 51608, Certoplast 531 and Coroplast 8550.

The model of EF9531C is approved by Delphi, and part No. is M6789

The model of EF9531D is approved by Delphi, and part No. is M5523

Test Standard

Meet the requirement of LV312

| Property | Unit | Test Standard | Remark |

| Total thickness | μm | ASTM-D-1000 | |

| Tensile strength | N/cm | ASTM-D-1000 | |

| Elongation at break | % | ASTM-D-1000 | |

| 180° peel strength to steel | N/cm | ASTM-D-1000 | |

| Temperature resistance | °C | VW60360(LV312) | |

| Abrasive resistance | Times | VW60360(LV312) | applicated for 9525 |

| Flame resistance | s | VW60360(LV312) | applicated for 9531C & 9531D &9532 |

| Unwind force | N/cm | ASTM-D-1000 | applicated for 9531 & 9532 |

Recommended uses

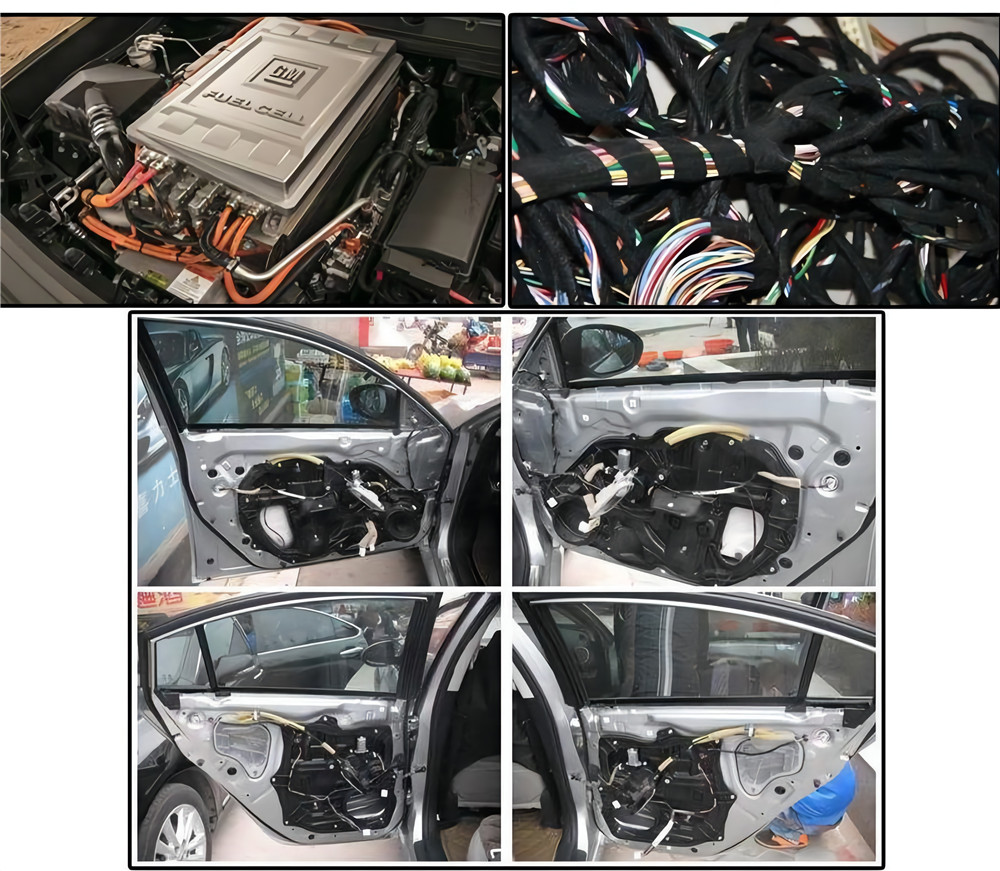

It is used for automobile wire harness wrapping. Its thick and soft characteristics determine that it has become an ideal product for automotive interiors and other environments that require noise reduction.

Advantages

✔ Noise reduction and environment friendly

✔ Extremely soft surface

✔ High tear resistance and stability

✔ High temperature stability

✔ Low temperature stability

✔ Flexible and easy to handle

✔ High adhesive force

✔ Stable against rotting

✔ Tearable by hand

✔ Free of critical substances

Application