Cable Protection & Sleevings

Cable protection series involve different materials Tapes, Cable Protection Grommets, Cable Sleeving, Cable Protection Tubes, Flexible Conduits, and Cable Protection Accessories. Typhoenix protection materials meet and exceed all current and normalized standards. All of them are produced by top manufacturers and get strict tests before delivery. They provide the best cable protection not only for the automotive wire harness industry but also for mechanical and plant engineering, trains and public buildings. The varieties of cable protection products range from high-quality Plastic, Fabric and Rubber can give you one-stop solutions for your cable protection systems. OEM and ODM service is available.

-

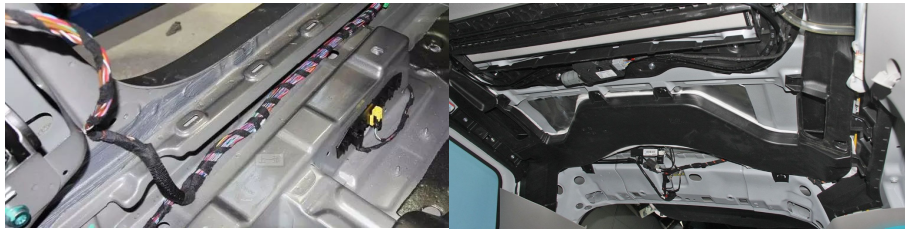

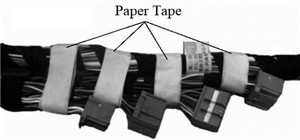

Tape

The adhesive tape plays the role of bundling, wear resistance, temperature resistance, insulation, flame retardant, noise reduction, marking, etc. in the automotive wire harness, and generally accounts for about 30% of the wire harness wrapping material. Our wire harness tape products include commonly used PVC tape, cloth tape, fleece tape, paper tape and foam tape (Sponge Tape), etc. The temperature resistance is 80℃, 90℃, 105℃, 125℃ or 150℃. -

Car Grommet

Car grommets are usually used in automotive doors for sealing, insulation, dustproof and waterproofing. We can provide different shapes and sizes of automotive wire grommets made of EPDM Rubber only or a hybrid of rubber and plastic or metal materials. We have our own technician team, so we also could provide OEM and ODM services. -

Convoluted Tubing

Corrugated tubing is also known as wire loom tubing. Corrugated tubing has good abrasion resistance, flame resistance and heat resistance. We provide corrugated pipes of different materials such as PP, PA6, PPmod, TPE, etc. The temperature resistance of corrugated pipes is between -40-175℃. Our bellows are all supplied by car -

PVC & PE Sleeving

PVC and PE sleeving have excellent electrical and physical properties, acid resistance and corrosion resistance. The flame retardant meets the standard of UL224, VW-1 and J QAF-mar, and the environmental protection meets the requirements of RoHS, REACH and SONY environmental protection standards. The standard temperature resistance is 105℃ and 125℃, and the color is generally black. We can provide custom service for inner and outer diameter, color, wall thickness and temperature resistance. -

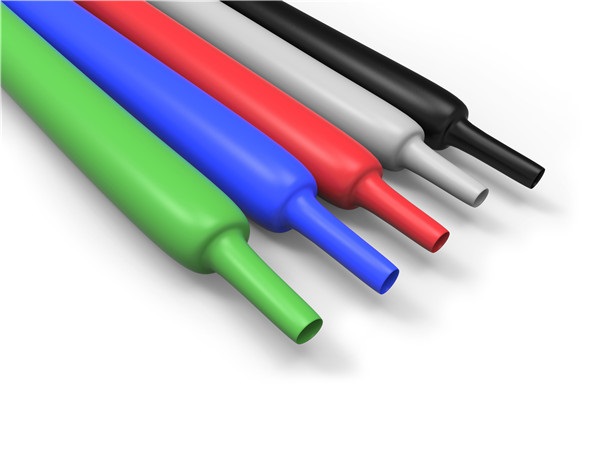

Heat Shrinking Tubing

Heat shrinking Tubing has excellent flame-retardant, insulating properties, soft and elastic, low shrinkage temperature, fast shrinkage, and can be widely used in wire connection, wire end treatment, solder joint protection, wire harness identification, insulation protection, corrosion protection, etc. Our products meet flame retardant and environmental protection requirements, and the performance index test methods are performed in accordance with UL224 and ASTM standards. Some products can replace TE (Raychem), Sumitomo, DSG-Canusa, Alpha, 3M and LG products. -

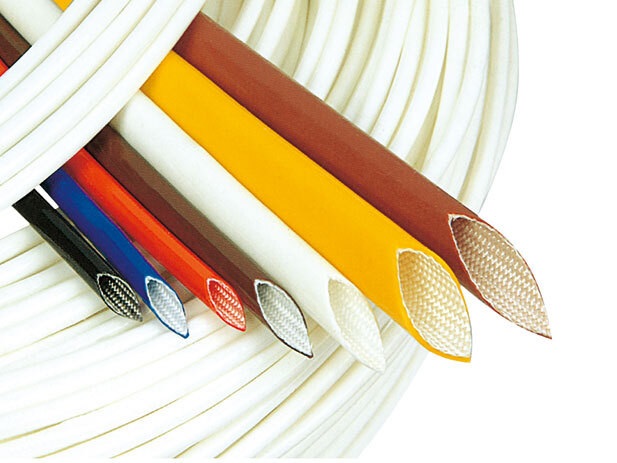

Fiberglass Tubing

Fiberglass Tubing, also known as fiberglass tubes, or fiberglass sleeves, are special kinds of fiber sleeves made of glass fiber woven into a tubular shape and processed by a high temperature setting process. Fiberglass tubes are divided into silicone resin fiberglass tubes and silicone rubber fiberglass tubes. Glass fiber tube has good insulation, flame retardancy and softness, and is widely used in not only the insulation protection of H&N grade motors but also household appliances, electric heating equipment, special lamps, televisions and electronic instruments. -

Braided Sleeve

Braided sleeves are also known as braided cable sleeves, cable sleeving, etc. The materials are divided into PET, PE, PA66, etc., with different appearances of split, closing and self-rolling, and the temperature resistance standard is generally 125 ℃ and 150 ℃. In addition to reducing noise, the braided sleeving has excellent abrasion and temperature resistance. The wiring harness sleeves provided by Typhoenix are all certified by UL, SGS, ROSH and IATF16949:2016. For any customization needs, please contact us. -

Other Cable Protection

You can find the other cable protection products hear.