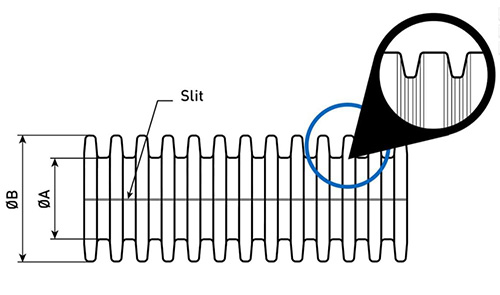

Convoluted tubing material PP Brand Delfingen SYFLEX PPAE 105℃

Basic information

|

Typhoenix Parts No. |

Delfingen No. |

ID A Ø (mm) |

OD B Ø (mm) |

|

BWG-05 |

SYFLEX 05 |

5.4 |

7.8 |

|

BWG-07 |

SYFLEX 07 |

7.4 |

10.2 |

|

BWG-10 |

SYFLEX 10 |

10.7 |

14.7 |

|

BWG-13 |

SYFLEX 13 |

13.2 |

17.5 |

|

BWG-15 |

SYFLEX 15 |

15.2 |

19.5 |

|

BWG-17 |

SYFLEX 17 |

17.3 |

21.7 |

|

BWG-19 |

SYFLEX 19 |

19.5 |

23.8 |

|

BWG-22 |

SYFLEX 22 |

22.1 |

27 |

Physical Properties Test

It is one of the important indexes of convoluted tubing performance. These tests have been carried out strictly in accordance with Specifications ISO 6722, 2410NDS00[7], RNDS-B-00217, FMVSS 302. The temperature resistance grade of this product is 105°C. The test requires that the product is free of defects in the environment of 125°C for a short time (240 hours) and 100°C for a long time (3000 hours). The specific test standards and test reports are shown in the following figure:

Packing information

♦ The convoluted tubing is packed in the strong 5-layer corrugated box of size: 800*600*600 mm

♦ Carton Packing Qty for Each Specification is as below:

|

ID |

Typhoenix No. |

Package specification |

Carton Size |

Carton Volume |

Carton Weight |

|

5 |

BWG-5 |

1000M/R*3 |

800X600X600 |

0.288 |

20.4 |

|

7 |

BWG-7 |

500M/R*3 |

800X600X600 |

0.288 |

16.2 |

|

8 |

BWG-8 |

350M/R*3 |

800X600X600 |

0.288 |

16.17 |

|

10 |

BWG-10 |

300M/R*3 |

800X600X600 |

0.288 |

15.39 |

|

13 |

BWG-13 |

200M/R*3 |

800X600X600 |

0.288 |

12.96 |

|

15 |

BWG-15 |

150M/R*3 |

800X600X600 |

0.288 |

10.53 |

|

20 |

BWG-20 |

100M/R*3 |

800X600X600 |

0.288 |

9.03 |

|

22 |

BWG-22 |

70M/R*3 |

800X600X600 |

0.288 |

7.94 |

♦ Sea Delivery Shipment Photo:

Brand Delfingen introduction

What does the convoluted tubing do?

The wire harness is the central nervous system of automobiles. Various harness binds are used to fix and protect it, and convoluted tubing accounts for 60% or even more. Because the convoluted tubing has its unique function in protecting the harness:

1.Protect

The convoluted tubing is the outermost part of the wire harness, so it can protect the wire body from wear and corrosion of the external environment

2. Shock absorption

The convoluted tubing has axial expansion capacity and radial expansion capacity. So, it can cushion the vibration.

3. High-temperature resistance

The wire harness is generally fixed in the slot in the engine compartment of the car, especially the wire harness around the engine. The car engine will produce high temperatures after long-term operation. If there is no protection, the insulation layer of the wire body will soften soon, so use it to protect the wire body from damage.

Why is 60% of the wire harness wrapping convoluted tubing?

☞ It is very soft and can be bent into different angles according to needs, which is unmatched by other materials.

☞ It is wear-resistant, high-temperature resistant, fireproof and flame retardant, easy to operate, economical and applicable.

☞ It can also be resistant to acid, alkali, corrosion and oil stain.

☞ It can also be resistant to high temperature and the temperature resistance is generally between -40~150℃.

The corrugated pipe materials

The commonly used materials for automobile wire harnesses include polypropylene (PP), nylon (PA6), polypropylene modified (PPmod) and triphenyl phosphate (TPE). Common inner diameter specifications range from 4.5 to 40.

● PP: The temperature resistance of PP corrugated pipe reaches 100 ℃, which is the most used one in the harness;

● PA6: The temperature resistance of PA6 corrugated pipe reaches 120 ℃, which is outstanding in flame retardancy and wear resistance;

● PPmod: PPmod is an improved polypropylene type with a temperature resistance of 130 ℃;

● TPE: TPE has a high-temperature resistance, reaching 175 ℃.