Wire Harness is a wiring component connecting various electrical equipment in the circuit, which is composed of connectors, terminals, wires, insulating protective sleeves and tape, etc. Wire processing is the basic step of wire harness production, before connecting wires to wire terminals, wires need to be cutting, stripping and other ways to prepare for use. It can be a tricky process and, if not done properly, a short or a connection break may happen.

First, use an Automatic Cutting Machine to cut the wire to the desired length. Then, strip the wire as required, that is, use an Automatic Stripping Machine to remove the insulation around the conductors, leaving the conductors exposed. Once After the cutting & stripping is completed, the wires will be further processed, i.e., heated or tinned.

Now Let’s discuss the process requirements of wire cutting and stripping detail.

Wire cutting is the most basic step of wire processing, that is, using automatic wire cutting machines and equipment to cut the cable into the required size according to the specifications specified in the processing technology.

Inspection preparation:

♦ The appearance of the wire is not damaged, and the wire diameter and color are correct

♦ The machine can operate normally

♦ Excellent without damage

♦ The operating platform shall be clean and free from residues of other products

Operational requirements

♦ The wire length after cutting shall be within the tolerance range.

♦ There shall be no scratch when cutting, and the cut section shall be flat.

♦ Each 50 or 100 pieces shall be tied with a tie rope, and every tie shall be clearly marked with its wire gauge and length, without error.

The importance of stripping is self-evident, and it is an important guarantee for well crimping of terminals, that is, the insulation of wire is stripped off by the Automatic Stripping Machine according to the size specified in the processing technology, and the conductors is exposed.

Operational requirements:

♦ The strip length must be within the tolerance range.

♦ The conductor may neither be damaged nor cut nor pulled.

♦ No damage is allowed to the insulation skin in the non-stripping area.

♦ No residual insulating is allowed in the stripping area, and the section must be smooth.

Calculation method of strip length

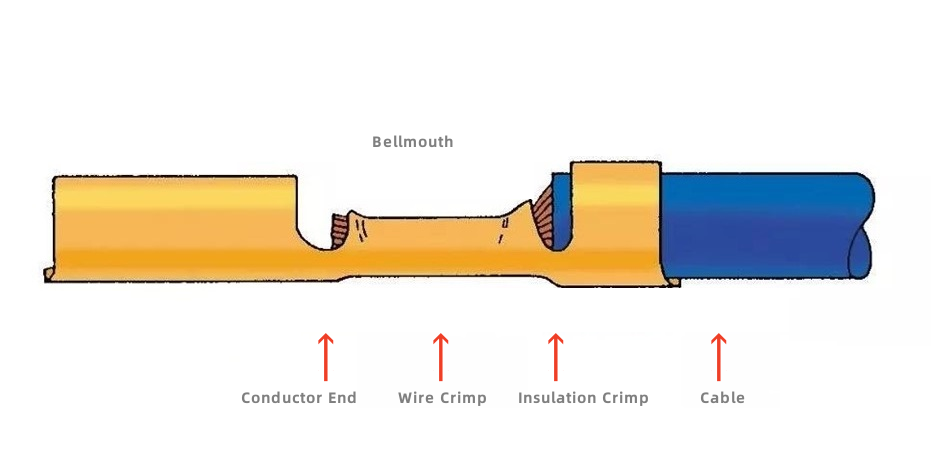

Stripping Length: Length of insulation to be removed from the end of a wire. The reference calculation method of strip length (refer to the general requirements, test methods and application guidelines of solderless crimping connection GB-T 18290.2-2000), as shown in the following figure:

Strip Length=Bellmouth Length +1/2a+0.5mm (wire size: below 0.3mm2)

Strip Length = Bellmouth Length +1mm (wire size:0.3-1mm2)

Strip Length = Bellmouth Length +2mm (maximum wire size:10mm2)

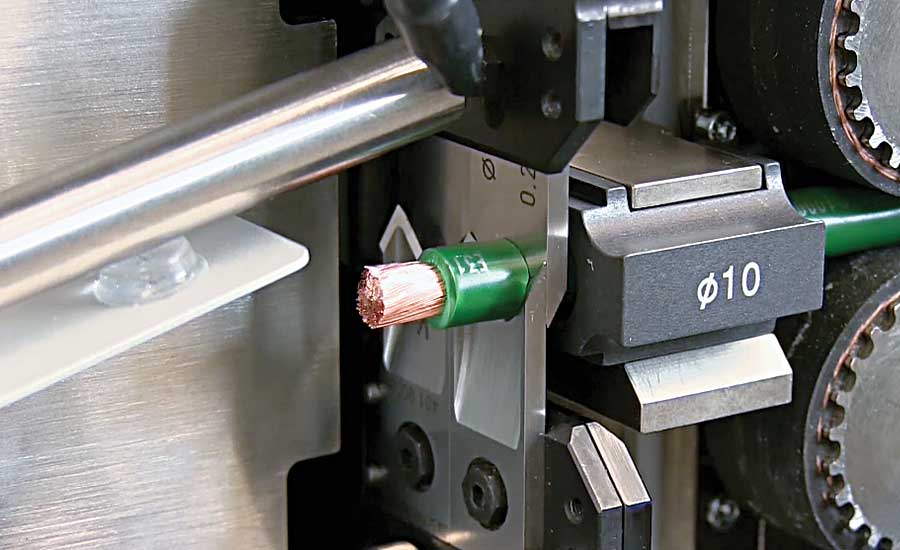

With the development of technology and the progress of equipment, Automatic Cutting and Stripping Machine, or Fully Automatic Equipment for Cutting, Stripping and Crimping has been available for decades. The Integrated Machine are more and more used to process wire now, which can save labor and efficiently complete the initial processing of wires. Therefore, generally, wire cutting, stripping, crimping and even other operations are carried out at the same time.

In addition, the wire stripper is one of the tools commonly used by electricians and repairmen, which is easy to operate and use.

Usage method

♦ Mark according to the cut length requirements

♦ Place the wire in the middle of the blade of wire cutter, hold the handle and cut the line with force

♦ Select the corresponding wire stripper knife according to the wire size

♦ Place the wire just cut in the middle of the blade of the wire stripping tool, and select the length to be stripped

♦ Hold the handle of the wire stripping tool, clamp the cable, and slowly use force to strip off the insulation

♦ Loosen the wire stripper handle and take out the wire. At this time, the conductor is exposed neatly and the insulation is intact

Any questions, feel free to Contact us now:

Website: https://www.typhoenix.com

Email: info@typhoenix.com

Contact: Vera

Mobile/WhatsApp: 0086 15369260707

Post time: Jul-25-2023