As the hub of information transmission, wire harness is related to the safety of vehicles and the reliability of electronic and electrical appliances. Therefore, automobile wire harness plays an important role in automobile composition and has high quality requirements. At the same time, automotive wiring harness are customized products, different vehicle manufacturers and different models have different design schemes and quality standards. With the improvement of automobile electrification and intelligence, the price proportion of wiring harness in the whole vehicle cost increases year by year.

Contents

2.1. More time-saving and easy standardization

2.2. Safer

2.3. More stable and efficient

2.4. Optimize space utilization

3.1 Large harness

3.2 Small harness

4.1 Wire

4.2 Terminals

4.3 Connector Housing and Accessories

4.4 Wire Seal,Plug and Interface Seal

4.5 Electrical boxes, Relays and Fuses

4.6 Harness Fixtures

4.7 Harness Protector

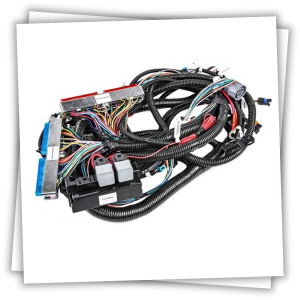

A automotive wiring harness is also known as a automotive cable harness, automotive cable assembly, automotive wiring assembly. It is a combination of circuit systems to realize all functional configurations of the vehicle.

Wire Harness is an indispensable system level component in the whole vehicle. Wire harness plays an important role in the composition of automobile. It provides and distributes power for each system of the whole vehicle, and acts as the medium of signal transmission between various components.

Automobile wire harness is the connecting body of automobile circuit and the carrier of transmitting electronic signals and electric energy. We can say that automobile harness is the blood vessel and nerve to connect automobile electrical system. Without harness, there will be no automobile circuit. Automobile harness is mainly composed of wires, terminals, connectors, harness protectors and fixings.

Compared with loose wires and cables, automobile harness has several advantages:

2.1. More time-saving and easy standardization

Aircrafts, vehicles, and spacecrafts typically have a vast network of wires that can extend for several kilometers if fully stretched out. However, rather than directly installing each wire individually, a harness can be used to bind multiple wires and cables together. This approach not only saves installation time but also makes standardization much easier. Moreover, it minimizes the risk of incorrect wiring.

2.2. Safer

The wire harness surface is usually wrapped with a layer of flame retardant protective materials, such as corrugated pipe, PVC pipe, heat shrinking tubing, electrical tape, Vinyl, etc. They can protect wires and cables and minimize the risk of circuit short circuit better. Tying wires in flame retardant sleeves can also reduce the risk of electrical fire.

2.3. More stable and efficient

By bundling many wires and cables into a cable bundle, the wires and cables can be better protected from the adverse effects of vibration, abrasion, high temperature and humidity, so that the car can still transmit electrical signals efficiently in a harsh environment. Even under extreme conditions, these wire harnesses can transmit high current, which can handle electrical loads and resist high heat and electromagnetic noise.

2.4. Optimize space utilization

As customized development products, different models have different harness design schemes. The development of automobile wiring harness and vehicle model are carried out simultaneously. At the beginning of automobile harness design, the direction and arrangement of harness are considered in order to make full use of space.

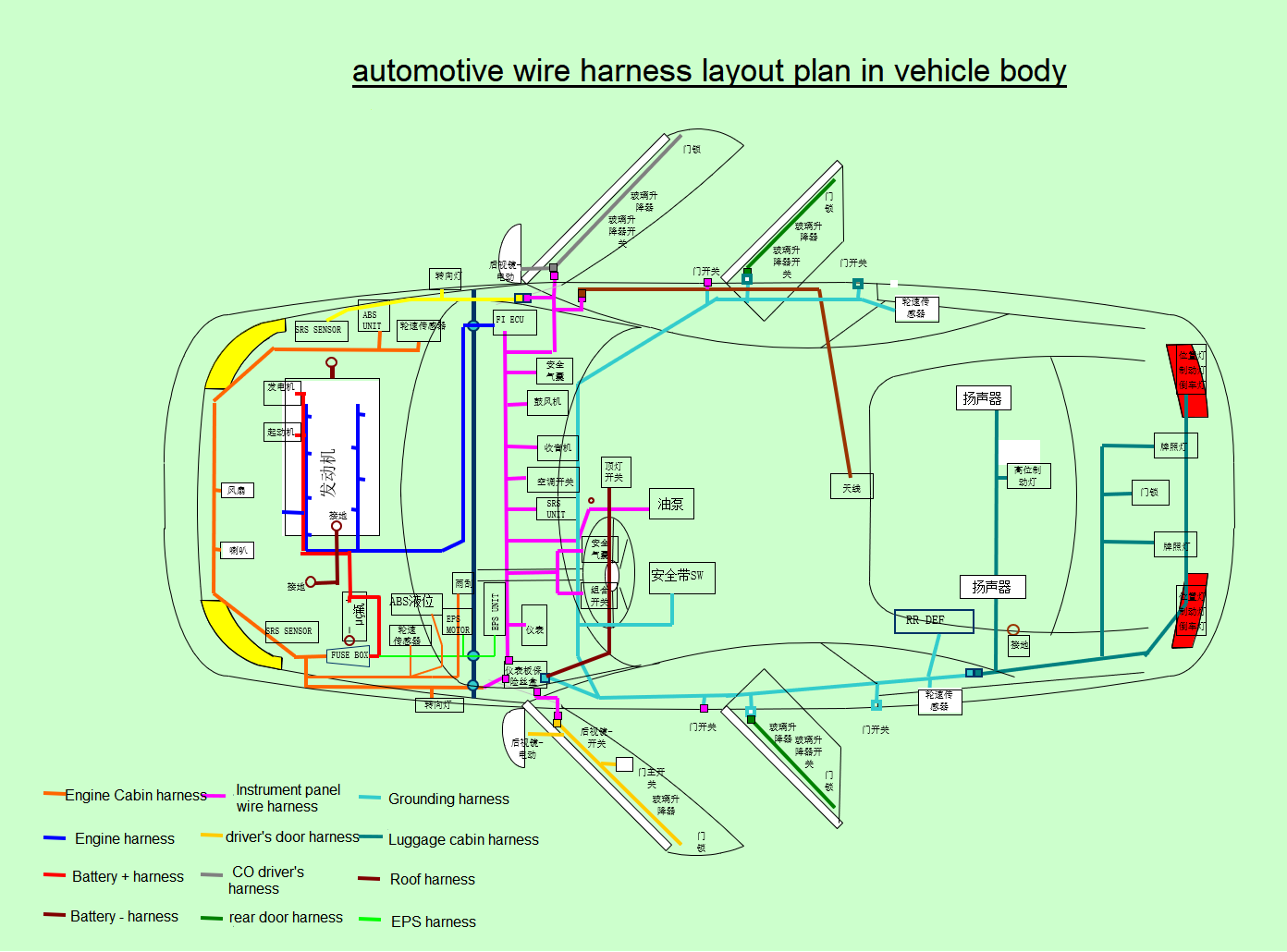

According to the complexity and use position of the wire harness, the automobile cable harness can be divided into large harness and small harness:

✔ 3.1 Large harness

● Engine wire harness, also known as engine cabin wire harness

● Fuse box wire harness

● Instrument panel wire harness

● Cabin wire harness, also called Body wire Harness

✔ 3.2 Small harness

● Door wire harness (driver's door harness, CO driver's harness, left and right rear door harness)

● Battery wire harness

● Roof wire harness

● Luggage cabin wire harness

● Reversing radar wire harness

● ABS brake wire harness

● Grounding wire harness

See automotive wire harness layout plan in vehicle body

Automobile wire harness usually consists of the following parts:

✔ 4.1 Wire

Automobile wire, also known as low-voltage wire, mainly plays the role of conducting current. It looks very similar to ordinary household wires, but they are different. Ordinary household wires are copper single core wires with a certain hardness. The automobile wires are copper multi core flexible wires. Some flexible wires are as thin as hair. Several or even dozens of flexible copper wires are wrapped in plastic insulating tubes (PVC), which are soft and not easy to break.

Due to the particularity of the automobile industry, The manufacturing of automobile harness must use special wires for automobile.

The automobile wire for manufacturing automobile wire harness can be roughly divided into two categories:

1. European and American systems:

TS16949 system is used to control the manufacturing process.

2. Japanese system:

For example, Toyota and Honda have their own systems to control the manufacturing process.

The commonly used car models are: Japanese standard AV, AVS, AVSS, AVX / AEX, German standard FLRY-B, FLRY-A, FLRYK-A, LRYK-B, FLRYW-A, FLRYW-B, American Standard GTE, GPT, GXL, SXL, TWE, TWP, TXL.

It's worth noting that wire colors are divided into monochrome and bicolor, each with a specified purpose set by vehicle manufacturers. While China's industry standard only specifies the main color, such as black for grounding wire harness and red for battery wire harness, to avoid confusion.

As vehicles become more advanced with increased electronic control technology and electrical parts, the number of wires in a harness also increases, leading to thicker and heavier harnesses. To address this, advanced vehicles have introduced the Can-Bus (Controller Area Network) and multiplex transmission system, which significantly reduces the number of wires and connectors required, making wiring easier than traditional wire harnesses.

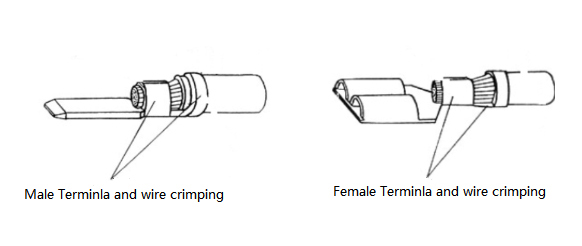

✔ 4.2 Terminals

Automotive Terminal is a metal medium used for signal transmission and energy conduction. Most of the terminals used in automobile harness are made of brass or phosphor bronze, and their structures are as follows:

Terminal classification methods

There are two common terminal classification methods:

● Distinguished by pairing attribute, terminals are divided into male terminals and female terminals;

● Distinguished by shape, terminals are divided into Blade Terminals, Socket Terminals and Splice Terminals. Among them, Splice Terminals can be divided into U-shape Terminals (also known as U terminals), Fork shape Terminals (also known as Y Terminals) and Ring Terminals (also known as R Terminals).

✔ 4.3 Connector Housing and Accessories

Automotive electrical connectors are electronic components that transmit and exchange current or signals between electronic system equipment. As a node, it transmits current or signal between devices, components, equipment and subsystems independently or together with cables, and maintains no change of signal distortion and energy loss between systems. It is a necessary basic element for the connection of the whole complete system.

The 'connector' can refer to the combination of terminal, housing, waterproof wire seals and accessories, or it can refer to the housing alone. The housing, namely the male and female connector housing, is the outer cover of the automotive electrical connectors, which is a plastic part to protect and fix the terminal and insulate it from the outside. It can provide mechanical protection for the interior and ensure the alignment of the plug and socket when they are inserted. The connector consists of a pair of male and female heads. The male connector is commonly known as "plug" and the female connector is commonly known as "socket". The male and female ends can transmit signal or current after contact. The male and female nature of the connector can strengthen safety and ensure the normal operation of the equipment.

Customer barriers in the automotive connector industry are high. In the automotive industry chain, in order to ensure the dynamic performance and safety performance of vehicles, vehicle manufacturers have high requirements for the quality and reliability of connector products, and the access qualification audit of upstream suppliers is more stringent. From the initial contact to the formal supplier system that becomes a customer, it will go through various audits such as contact, technical exchange, business system, quality system and technical system. Suppliers are required to have product R & D ability, process control ability, supply guarantee ability, product test and inspection ability, parts production guarantee ability and after-sales service ability. It takes a long time to enter the supplier system.

There are four most commonly used materials for sheath: PA, PBT, PP and ABS.

The automotive electrical connectors we sell come from factories with supporting experience and iso16949 certification. The quality is guaranteed, the price is cheap and the delivery time is timely. Welcome to check our connector products.

✔ 4.4 Wire Seal,Plug and Interface Seal

All three are limited to used in waterproof connectors. The wire seal is a rubber structural part crimped on the wire insulating skin to prevent the penetration of liquid from the connector hole, while the blind plug is a rubber structure that blocks the unused hole in the connector to prevent water. It is generally made of silica gel, and the size is very small. The Interface seal is a rubber structural part used to prevent liquid infiltration. It is generally made of silica gel, and its size is larger than wire seal and plug.

We choose them from the TE OEM factory. Quality is very good, but price is only half of the original ones. You can contact us for our catalogue.

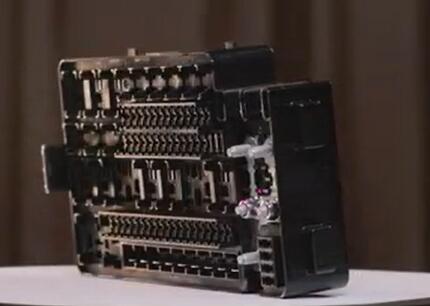

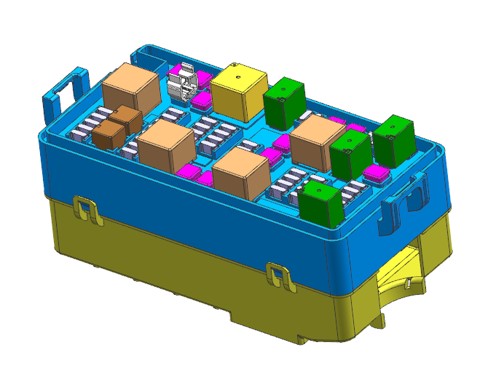

✔ 4.5 Electrical boxes, Relays and Fuses

Electrical box is also called fuse box, Power distribution.

The automotive electrical box is divided into the following three types from the structural characteristics and processing technology:

1. In-line electrical box

The internal conductive part of the in-line electrical box is composed of several conductive copper plates and externally inserted wire crimping terminals to complete the corresponding power distribution circuit. Because it needs to be directly connected to the wire harness terminal, it is generally assembled with the wire harness in production. It is characterized by the ability to distribute high current power, simple structure, compact layout and low cost.

2. Bus bar electrical box

The conductive parts inside the busbar type electrical box are all power distribution circuits composed of stamped conductive copper plates. It is characterized by high connection reliability and independent from the wiring harness.

3. Printed circuit board (PCB) electrical box

The conductive part inside the PCB-type electrical box completes the power distribution through the printed circuit board. It is characterized by low cost, easy mass production, and flexible layout and assembly on the vehicle. Some PCB electrical boxes will integrate a control unit, which is equivalent to having the function of BCM. In this way, the integration of the electronic and electrical architecture of the vehicle is very high,

Generally speaking, the body of the engine compartment fuse box adopts a PCB-type electrical box, which is used to control and protect the starter, generator, engine EMS, fuel pump, Electrical systems such as cooling water pumps, vacuum pumps, cooling fans, air conditioning compressor clutches, and electric power steering. The cockpit fuse box body adopts an in-line electrical box, which is used to control and protect the body controller, combination instrument, door lock system, interior lighting, interior and exterior mirrors, seat adjustment system, audio navigation and other electrical systems. Electrical boxes are generally dedicated to special vehicles and need to be developed according to the model. See our Fuse Box catalogue to check our exiting fuse box.

In addition to terminals and stamped conductive copper plates, there are fuses and relays on the electrical box. The fuses we sell are the car fuse series of the Littelfuse brand. The relays are selected from brand relays with supporting experience.

|

|

|

✔ 4.6 Harness Fixtures

There are Positioning clips, cable ties, rubber parts, wire harness brackets, etc. for fixing automotive wire harnesses.

✔ 4.7 Harness Protector

Protective tapes, corrugated pipes, PVC pipes, heat shrinkable pipes, glass fiber pipes, braided sleeves, etc.

Any questions, feel free to Contact us now:

Website: https://www.typhoenix.com

Email: info@typhoenix.com

Contact: Vera

Mobile/WhatsApp: +86 15369260707

Post time: Aug-07-2023