An automotive wire harness connector is a specialized connector used to connect wires and cables within an automotive wire harness. The automotive wire harness connector serves the purpose of connecting and protecting the wires, ensuring reliable electrical signal transmission, and providing protection and insulation. Here is an introduction to automotive wire harness connectors:

Automotive wire harness connectors are used to connect the wires and cables within a wire harness to the electronic devices, sensors, switches, and other electrical components in a vehicle. They provide a reliable electrical connection, ensuring the transmission of power and signals while offering protection and insulation to safeguard the connection from external environmental factors.

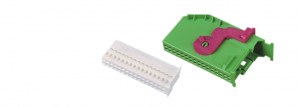

The structure and design of automotive wire harness connectors are carefully engineered to meet the specific requirements of automotive applications. They typically consist of a plug (male) and a socket (female) , which are designed to interlock securely and provide a reliable electrical interface. The plug, often referred to as the mating connector, is attached to one end of the wire harness, while the socket, known as the receptacle connector, is integrated into the corresponding electrical component or device.

One of the key features of automotive wire harness connectors is their ability to ensure robust and consistent electrical connections. This is achieved through the use of terminals, which are metal components within the connector that establish the electrical contact between the wire harness and the component. The terminals are designed to provide a secure and low-resistance connection, minimizing electrical losses and ensuring efficient power and signal transmission. The terminals may take various forms, including pins, sockets, blades, and crimp terminals, depending on the specific connector design and application requirements.

In addition to facilitating electrical connections, automotive wire harness connectors offer several other essential functions. They provide mechanical support and strain relief, ensuring that the wires within the harness are properly secured and protected against excessive tension, vibration, and mechanical stress. This helps to prevent wire fatigue, wire breakage, and potential electrical failures due to mechanical factors.

Furthermore, automotive wire harness connectors often incorporate sealing and insulating features to protect the electrical connections from external environmental conditions. They may utilize grommets, seals, or rubber gaskets to provide resistance against moisture, dust, dirt, and other contaminants. This ensures the connectors' longevity and reliability, even in demanding environments such as engine compartments or underbody applications where exposure to harsh conditions is common.

Automotive wire harness connectors are manufactured using materials that exhibit excellent electrical conductivity, mechanical strength, and resistance to temperature variations and chemical exposure. Commonly used materials include various metals like copper, brass, and aluminum for the terminals, and insulating materials such as thermoplastics, thermosetting plastics, or rubber for the connector housing. The choice of materials depends on factors such as the electrical requirements, environmental conditions, and manufacturing considerations.

Depending on the specific application and requirements of the wire harness, various types of wire harness connectors exist. For example, wire harness connectors can differ based on the number of wires and terminals, such as single-wire connectors, multi-wire connectors, single-terminal connectors, and multi-terminal connectors.

It is worth noting that automotive wire harness connectors are subject to industry-specific standards and regulations to ensure their quality, reliability, and compatibility. International standards organizations, such as the International Organization for Standardization (ISO) and automotive industry bodies, establish guidelines and specifications for connector design, performance, and testing. Compliance with these standards helps guarantee the proper functioning and interoperability of wire harness connectors across different vehicle manufacturers and models.

Automotive wire harness connectors play a crucial role in establishing reliable electrical connections within an automobile's electrical system. They provide a secure, efficient, and durable interface for power and signal transmission, while also offering mechanical support, strain relief, and environmental protection. With their carefully engineered design, high-quality materials, and adherence to industry standards, automotive wire harness connectors contribute to the overall safety, performance, and longevity of modern automotive electrical systems.

Any questions, feel free to Contact us now:

Website: https://www.typhoenix.com

Email: info@typhoenix.com

Contact: Vera

Mobile/WhatsApp: 0086 15369260707

Post time: Jul-06-2023